Page 2 of 2

Re: Making Different Mills Vendor Mints

Posted:

Thu Jun 09, 2016 2:00 amby JHSS-1944

Rick; I was joking on the reel strips...... BUT , you do do fine work. actually these strips were casino made , not to be found out & about being reproduced.

the price on the "mints" sounds good !

jeff H.

Re: Making Different Mills Vendor Mints

Posted:

Tue Jun 14, 2016 8:35 amby flipper77

Had to have some of these Mills mint rolls from friend Rick B. They are terrific! Needed a few for my War Eagle side vender (picture). They looked so good that I committed a major sin - Mills wintergreen mints in my - - - - - Rol-A-Tor! They just looked so much better than my Pointers wrappers on the wooden dowels. Great idea and execution from Rick B.

Flip

Re: Making Different Mills Vendor Mints

Posted:

Tue Jun 14, 2016 10:19 amby Richard13

I agree those wrappers are great. Can't wait to "roll" a few up myself, pun intended!

Re: Making Different Mills Vendor Mints

Posted:

Wed Jun 15, 2016 5:21 pmby Rick B

Thanks Guys and I have 50 done and ready to go. It takes me about 1.5 hours to make that many. I cut the dowels and sand the edges round slightly. I then have to cut up the tin foil and print out the pages we cut out for the labels. Cost is foil, ink & dowels plus lots of time. My youngest daughter helps out also and we enjoy the time. I love shop time. Picture is of part of my shop below. Rick B

Re: Making Different Mills Vendor Mints

Posted:

Wed Jun 15, 2016 5:47 pmby Richard13

I would bet you could maybe 30-40 dowels for wrapping out of each of those garand stocks if you cut them right on a band saw then ran them in a lathe, and cut to length. More shop time save money on store bought dowels and smell the walnut sawdust as the wood is being re worked!

Nice shop BTW!

Re: Making Different Mills Vendor Mints

Posted:

Wed Jun 15, 2016 9:51 pmby SLOT DYNASTY

Richard13 wrote:I would bet you could maybe 30-40 dowels for wrapping out of each of those garand stocks if you cut them right on a band saw then ran them in a lathe, and cut to length. More shop time save money on store bought dowels and smell the walnut sawdust as the wood is being re worked!

I don't think I want to hear Richard's answer to this one!

Re: Making Different Mills Vendor Mints

Posted:

Thu Jun 16, 2016 1:29 amby JHSS-1944

Nice shop for sure , "when I grow up , I want one just like it...."

And NO... to cutting up stocks for dowels !!!

jeff H.

Re: Making Different Mills Vendor Mints

Posted:

Thu Jun 16, 2016 6:04 amby Richard13

What's the big deal I thought it was a GARAND IDEA bwahaha

Re: Making Different Mills Vendor Mints

Posted:

Sat Aug 06, 2016 5:26 pmby Rick B

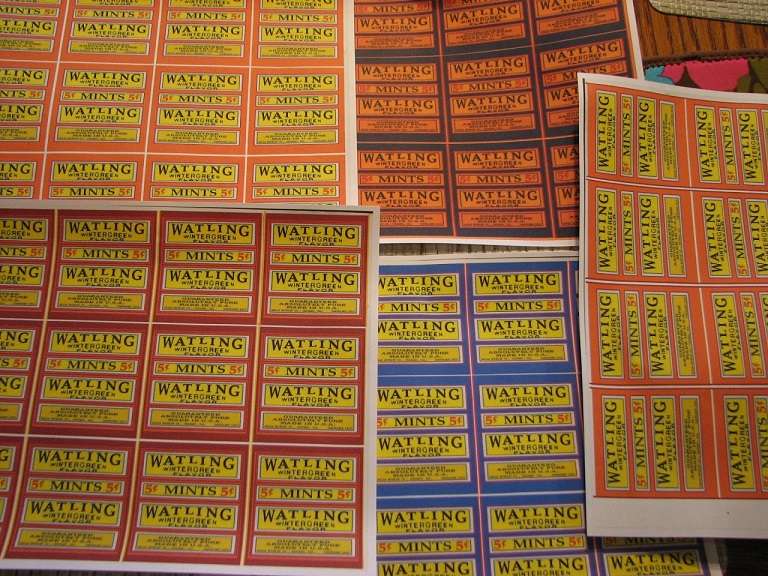

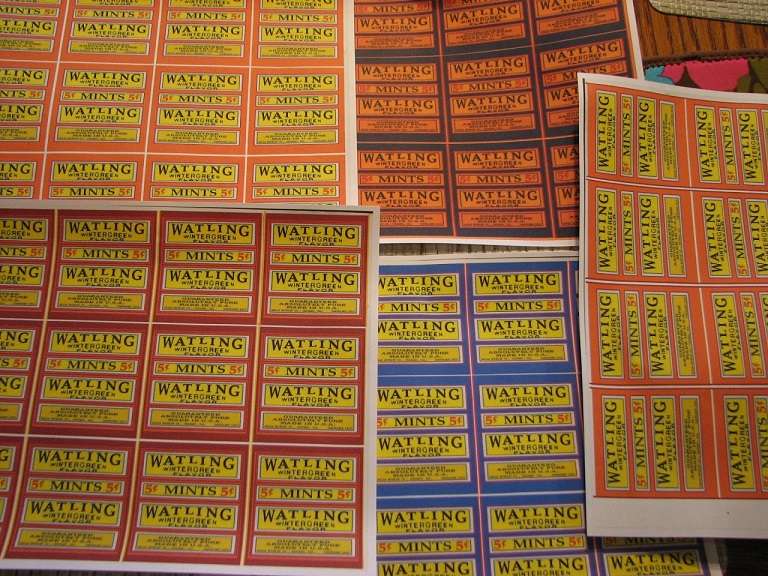

Added a few differnt ones to the mix tonight. Watling. Rick B